Anatomy of a Finished Banner

Every KBW banner is carefully crafted and professionally designed. Our method of crafting the perfect banner has been developed over the years to make sure every part of your banner holds strong no matter the conditions. Mixing simplicity with efficiency, the banners from Kalamazoo Banner Works are easy to hang and made to last.

1. Interior Banners

All interior top and bottom hems are single rolled and single stitched. This is a less bulky solution that allows for a cleaner presentation when on DisplayOne products.

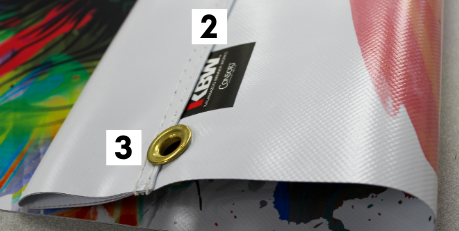

2. Exterior Banners

All exterior top and bottom banner hems for banners over 48″ long are double rolled and double stitched. Banners 48″ and shorter have single rolled hems. For banners larger than 24″ x 48″ in size, Consort recommends using a 4″ hem. For banners smaller than 24” x 48″, a 3″ hem is preferable.

3 .Grommets

Consort uses #2 brass spur grommets on its exterior banners. This allows wire ties to go through the grommet and the hardware, anchoring the banner tight to the pole.

4. Side Seams

Sunbrella® marine acrylic banners are sewn with 1/2″ side seams to prevent the material from fraying. Depending on other materials used such as vinyl, side seams may or may not be needed.